When the drone (unmanned aerial vehicles, or UAVs) craze took off nearly a decade ago, it was impossible for experts to predict how rapidly impactful the revolutionary technology would become. As sales began to dwarf estimates, professional drone pilots found new and innovative ways to utilize the technology economically, often as a safe and cost-effective alternative to manned aerial operations or underground imaging.

When the drone (unmanned aerial vehicles, or UAVs) craze took off nearly a decade ago, it was impossible for experts to predict how rapidly impactful the revolutionary technology would become. As sales began to dwarf estimates, professional drone pilots found new and innovative ways to utilize the technology economically, often as a safe and cost-effective alternative to manned aerial operations or underground imaging.

In 2016, United Power recognized it needed to brainstorm new ways to inspect its infrastructure in a quicker, safer and more efficient manner.

On a daily basis, electrical poles and cross arms are exposed to various weather conditions, which can cause accelerated decay over time. United Power’s linemen put their lives on the line to regularly ensure lines and poles delivering power to families around the service territory are in the best shape. Even in the best conditions, however, the effort necessary to inspect thousands of poles across thousands of miles of line is immense, if not impossible.

The idea to incorporate drone technology was first suggested by Mike Robinson, a Safety Specialist with the cooperative, who had been an early adopter of using drones during inspection.

United Power partnered with Colorado Aerial Imaging, a veteran-owned drone maintenance business with experience in electric line inspection, and began a trial implementation in the Mountain Territory.

Mountain Territory

Coal Creek is a 215-square mile noncontiguous parcel of land served by United Power. Extending from Golden to the Continental Divide, the Mountain Territory is sparsely populated, requiring lots of line carrying a higher voltage. The higher voltage lines, rugged terrain and severe weather made the Mountain Territory an easy place to begin initial implementation for the drone maintenance program.

With poles perched on cliff sides, in dense forests and at high elevations, inspection is a risky endeavor for linemen in Coal Creek. The time-consuming process also takes a backseat to restoring power during an outage, which can be exacerbated during storms and winter weather. UAVs provide quicker access to hard to reach poles and limit exposure to risk.

“The process of identifying and correcting an issue on a pole in a place like Coal Creek can require multiple hours to complete,” said Chief Operating Officer Bryant Robbins. “If another problem occurs during inspection, the linemen have no choice but to abandon it and return to it later.”

For linemen in Coal Creek, hiking in and out of an area multiple times to repair poles is not uncommon, but the task is no less daunting in United Power’s larger Plains Territory.

Plains Territory

Colorado Aerial Imaging recently completed its first phase in the Plains Territory near Brighton, with two more phases scheduled for the upcoming months. While the service territory is more favorable for weather and terrain, it still comes with challenges.

“We try to remain respectful of people’s concerns about privacy and security,” said Don McDaniel, Engineering Director for United Power. “It’s more densely populated, and more of our poles are located on or near private property.”

Since drones eliminate the need for linemen to approach poles during inspection, there’s limited impact to members — no property intrusion or interrupted service — and a sense of respect for their privacy.

Though linemen on the plains don’t have to hike to and from poles through dense foliage and up steep inclines, the time necessary to inspect poles would be exorbitant. Crews rarely have the ability to devote large parts of their day to inspection across the service territory.

“We serve some of the fastest growing areas in the Northern Front Range,” said McDaniel. “We have a lot of requests for new service from residential communities and businesses moving in, and not enough linemen to dedicate solely to inspecting poles, as much as we’d like to be able to.”

Other Benefits

“While examining and analyzing pole damages for an area in Coal Creek, we noticed rot along the top of a cross arm,” said Greg Bergin, co-owner of Colorado Aerial Imaging. “From where we were standing, the pole looked to be in fairly healthy condition.”

Because drones are not limited to the area around the pole, they are able to capture images from angles linemen wouldn’t otherwise be able to see.

“Without physically climbing the pole and inspecting every part of it for damage, we wouldn’t have noticed this damage without the use of drones,” said lineman Adam Dillion. “Some poles may look fine, even from our best vantage points, but the pictures from above tell another story.”

Aerial images obtained from drones are visual, thermal and geotagged, providing a broader, wider and higher view of each pole and piece of equipment. There’s an inherent redundancy built into the program to ensure accurate inspections.

“Before we ever send out a crew, we are able to determine what tools and materials we’ll need, how many men are required and whether we’ll need to be on someone’s property,” said Dillon.

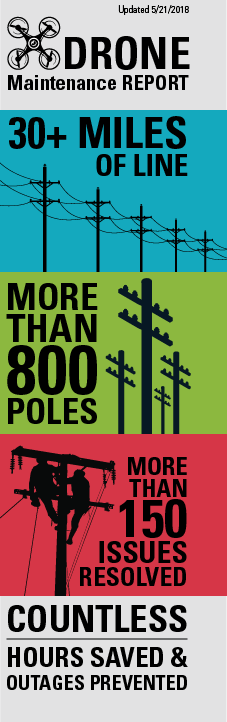

To date, Colorado Aerial Imaging has inspected more than 30 miles of line and nearly 800 poles.

“What may take a line crew more than a day to complete a drone is able to do in less than an hour,” Robbins said. “Our drone program has been a cost-effective way to stay proactive, instead of reactive, to the potential for outages on our lines. The amount of time and risk this program has saved us, and will continue to save us, is incalculable.”